Sun Rise relies on advanced production equipment and 30+ years of pipeline construction experience to provide high-quality HDPE pipes and accessories. In addition to extrusion machines, the factory is also equipped with a variety of injection molding machines, including a 3,000-ton large-scale injection molding machine that can produce one-piece spare parts up to 60 kgs. Sun Rise provides 6 types of accessories to meet different requirements, and each product undergoes strict quality control to ensure its reliability and durability in various environments.

- Type

- Specification

1. Electrofusion Fittings

Feature:

- Using internal resistance wire heating to melt the pipe and fittings so that they are firmly welded together.

- High intensity and reliability, suitable for permanent connections.

- Can be operated in a small space and is convenient for construction.

Application:

- High-pressure pipeline systems, such as natural gas, water supply and industrial pipelines.

- Applications that require high-intensity connections, such as underground pipes that require non-leaking risk.

- Harsh environment: suitable for use in harsh conditions such as underground and underwater.

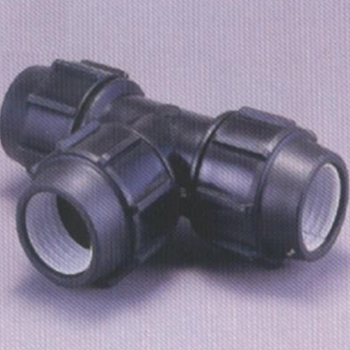

2. Screw Type Fittings

Feature:

- Connected by screws, and usually has a rubber seal to ensure there’s no leaking risk.

- Easy to install and remove, no special tools required.

- Reusable and easy to maintain.

Application:

- Temporary pipeline systems, such as temporary water and drainage systems.

- Repair and renovation: ideal for piping systems that require frequent disassembly and reconnection.

- Small diameter pipe: usually used for small diameter pipe connections.

Please refer to the installation of: Screw Type Fittings

3. Socket Fusion Fittings

Feature:

- Using heat to insert the pipe into the fitting to form a strong connection.

- The interface is smooth, reducing internal fluid resistance.

- High intensity, suitable for long-term use.

Application:

- Small to medium diameter pipes, such as domestic water supplies and small industrial pipeline systems.

- Applications that require smooth internal connections: ideal for systems requiring less fluid resistance.

- For pipeline systems in residential and commercial buildings.

Please refer to the installation of: Socket Fusion Fittings

4. Butt Welding Fittings

Feature:

- By heating pipes at both ends and welding them together.

- The joints are seamless and smooth inside and out.

- Has the highest intensity and pressure resistance.

Application:

- Large and high-pressure pipeline systems, such as municipal water supply, sewage treatment and industrial pipelines.

- Long-distance pipelines, such as oil pipelines and gas pipelines.

- Applications that require high intensity and pressure resistance.

Please refer to the installation of: Butt Welding Fittings

5. Channel Fittings

Feature:

- Has external or internal channels that can connect with other fittings.

- Quick installation, no welding or glue required.

- Easy to maintain and disassemble.

Application:

- Industrial and commercial building pipelines, such as air conditioning systems and fire protection systems.

- Temporary pipelines, such as pipeline systems for exhibitions or temporary facilities.

- Applications requiring quick installation and disassembly.

Please refer to the installation of: Channel Fittings

6. Plug-in Fittings

Feature:

- By inserting pipes into the fittings and using a seal ring to connect.

- Easy to install, no special tools required.

- The connection is strong and suitable for medium pressure systems.

Application:

- For domestic water supply systems and light industrial drainage systems.

- Easy repair: ideal for applications requiring simple and quick repairs.

- Small diameter pipes: suitable for small and medium diameter pipe.

Please refer to the installation of: Plug-in Fittings

Screw Type Fittings

| Coupling | OD (mm): 16, 20, 25, 30, 40, 50, 65, 75, 100 | ||||

|---|---|---|---|---|---|

|

|

||||

| 45 deg. elbow | OD (mm): 50, 75, 100 | ||||

|

|

||||

| 90 deg. elbow | OD (mm): 16, 20, 25, 30, 40, 50, 65, 75, 100 | ||||

|

|

||||

| Tee | OD (mm): 16, 20, 25, 30, 40, 50, 65, 75, 100 | ||||

|

|

||||

| Flange fitting | OD (mm): 75, 100 | ||||

|

|

||||

| Reducing Tee | 20×16 25×16 25×20 30×16 30×20 30×25 |

40×16 40×20 40×25 40×30 |

50×16 50×20 50×25 50×30 50×40 |

65×50 75×20 75×25 75×30 75×40 75×50 |

100×50 100×75 |

|

|

||||

| Reducer | 20×16 25×16 25×20 30×20 30×25 |

40×20 40×25 40×30 |

50×20 50×25 50×30 50×40 |

65×50 75×50 75×65 100×75 |

|

|

|

||||

| Plug | OD (mm): 16 20 25 30 40 50 65 75 100 | ||||

|

|

||||

| Plug | OD (mm): 16, 20, 25, 30, 40, 50, 65 | ||||

|

|

||||

| Saddle | 16×75 16×100 16×150 |

20×75 20×100 20×150 |

25×75 25×100 25×150 |

30×75 30×100 30×150 40×100 40×150 |

|

|

|

||||

Socket Fusion Fittings** also comes in JIS standard

| Coupling |  |

|||

|---|---|---|---|---|

| OD (mm): 20, 25, 32, 40, 50, 63/td> | ||||

| female-threaded elbow |  |

|||

| OD (mm): 20, 25 | ||||

| 90 deg. elbow |  |

|||

| OD (mm): 20, 25, 30, 40, 50, 63 | ||||

| Tee |  |

|||

| OD (mm): 20, 25, 32, 40, 50, 63 | ||||

| Male-threaded coupling |  |

|||

| OD (mm): 20, 25, 32, 40, 50, 63 | ||||

| Reducer |  |

|||

| 25×20 32×20 32×25 |

40×20 40×32 |

50×20 50×25 50×32 50×40 |

63×25 63×32 63×40 63×50 |

|

| Tee |  |

|||

| 25×20 32×20 32×25 |

40×20 40×32 |

50×20 50×25 50×32 50×40 |

63×25 63×40 63×50 |

|

Butt Welding Fittings**also comes in JIS standard

| 90 deg. elbow | A). One-piece injection molding 75, 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315 B). welding 355, 400, 450, 500, 560, 630, 710 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 deg. elbow | A). One-piece injection molding 75, 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315 B). welding 355, 400, 450, 500, 560, 630, 710 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flange | A). One-piece injection molding 25, 32, 40, 63, 75, 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tee | A). One-piece injection molding 75, 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315 B). Welding 355, 400, 450, 500, 560, 630, 710 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Reducer | A). One-piece injection molding

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tee | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Channel Fittings

| pressure ring | OD (mm): 50, 75, 100, 125, 150 | |||

|---|---|---|---|---|

|

|

|||

| 90 deg. elbow | OD (mm): 50, 75, 100, 125, 150 | |||

|

|

|||

| 45 deg. elbow | OD (mm): 50, 75, 100, 125, 150 | |||

|

|

|||

| Plug | OD (mm): 50, 75, 100, 125, 150 | |||

|

|

|||

| Tee | OD (mm): 100 | |||

|

|

|||

| Tee | 50 50X75 70 |

100 100×40 100×50 100×75 |

125 125×50 125×75 125×100 |

150 150X100 |

|

|

|||

| Tee | 50 50X75 70 |

100 100×40 100×50 100×75 |

125 125×50 125×75 125×100 |

150 150X100 |

|

|

|||

| Reducer | 50×75 | 100×50 100×75 100×125 |

125×150 | |

|

|

|||

Plug-in Fittings

| Coupling | OD (mm): 40, 50 | ||||

|---|---|---|---|---|---|

|

|

||||

| 90 deg. elbow | OD (mm): 40, 50 | ||||

|

|

||||

| 45 deg. elbow | OD (mm): 40, 50 | ||||

|

|

||||

| Plug | OD (mm): 40, 50 | ||||

|

|

||||

| Reducer | OD (mm): 50x40 | ||||

|

|

||||

| Elbow | OD (mm): 50 | ||||

|

|

||||

| Tee | OD (mm): 40, 50 | ||||

|

|

||||

| Connector | OD (mm): 50, 75, 100 | ||||

|

|

||||