High-density polyethylene (HDPE) pipes are widely used in our daily lives and various engineering projects, covering tap water, electricity, gas, sewage, industrial and agricultural irrigation and other fields. The complete sealing, high elasticity and durability, and low maintenance costs make it the perfect material choice for modern piping systems. HDPE pipes come in a wide range of outer diameters and can be used in different applications. Whether in homes, cities or industrial scenarios, HDPE pipes provide reliable and efficient solutions.

- For different pipe applications

- Other pipes

- Packing methods

Please click the link below for more information:

Specification table

Regular application

High-pressure application

Gasoline/air application

Water/electricity/domestic application

Regular Pipeline Applications:

1. Water Supply System

HDPE pipe is ideal for water supply systems because of its corrosion resistance, pressure resistance, non-toxicity and long service life. It commonly comes in a black pipe with blue line.

Often used in:

- Residential water supply: usually from diameter 20mm to 63mm.

- Municipal water supply: from 110mm to 630mm or larger diameter.

2. Sewage & Drainage Treatment

HDPE pipes are widely used in drainage and sewage treatment mainly because of their chemical and corrosion resistance. The designs are all black pipes (drainage), black pipes with purple line (reclaimed water), and black pipes with orange line (sewage). The application includes:

- Household drainage: from 32mm to 110mm. To be used for kitchen, bathroom, and laundry drainage.

- Municipal drainage and sewage treatment: from 250mm to 1000mm.

3. Gasoline Transportation

HDPE pipe is also suitable for gas transportation because of its excellent pressure and leakage resistance. The design is a black with yellow line. The application includes:

- Household gas transportation: from 20mm to 63mm.

- Municipal gas transportation: from 90mm to 315mm.

4. Industrial Application

HDPE pipes are suitable for transporting various kinds of liquids and gases, including:

- Chemical: from 50mm to 400mm. To be used in transportation of chemicals and industrial waste water.

- Mining: from 160mm to 800mm. To be used in transportation of slurry.

5. Agricultural Application

HDPE pipes are widely used in agricultural irrigation systems mainly for its weather resistance and flexibility. The application includes:

- Drip irrigation: from 16mm to 32mm.

- Field irrigation: from 63mm to 160mm.

6. Electrical Cable Protection

HDPE pipe is also used to protect underground electrical cables from damage and chemical corrosion. The design is a black pipe with red line. Regular sizes are as follows:

- Communication cable protection pipe: from 50mm to 160mm.

- Electrical cable protection pipe: from 90mm to 250mm.

7. Hydraulic Engineering

HDPE pipes are suitable for hydraulic projects due to their UV and corrosion resistance properties. The application includes:

- Seawater transportation: transportation of water to remote islands, as well as transportation of natural gas, petroleum, collection of seawater, and discharge of sludge.

- River channel dredging: outer diameter from 250 mm to 800 mm for transportation mud.

1. CD Pipe

CD pipe is used to protect wires and cables. Due to its corrugated appearance, it has the ability to withstand external pressure and is also flexible. Usually used in places that require flexible wiring, such as electrical installations in residential and commercial buildings. It will not be squashed when cast in cement. With CD pipes, the quantity of elbows and construction time and cost can also be reduced. The following are the characteristics of CD pipes:

- Flexibility: easy to install in small spaces or places that require pipe bending.

- Light: easier for transportation and installation.

- Anti-corrosion: for use in humid environments or exposure with chemicals.

- Good insulation: Can effectively prevent electrical accidents.

- Cost-effective: Generally more economical than metal pipes, especially suitable for large-scale projects.

Spec: OD 2.54cm and 5.08cm

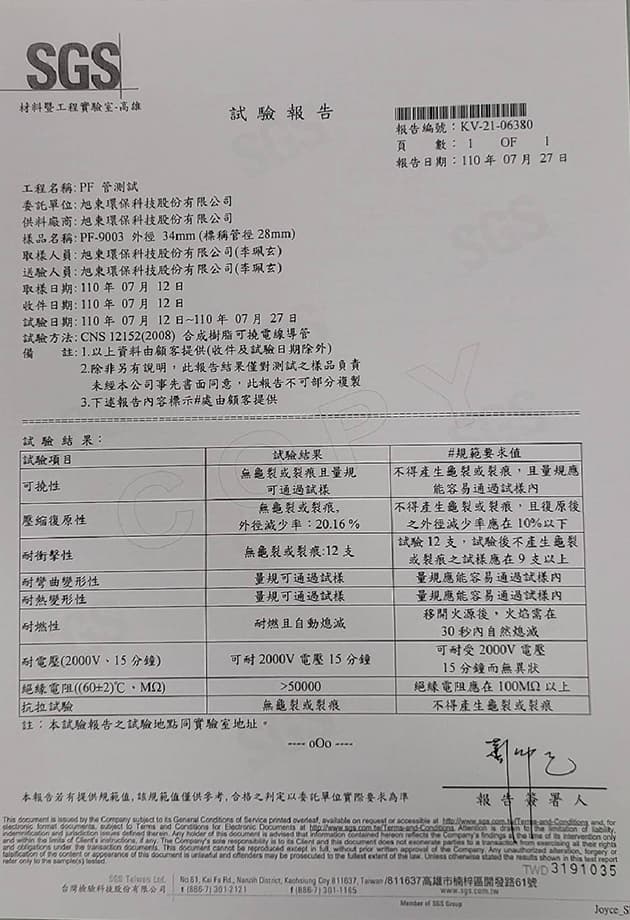

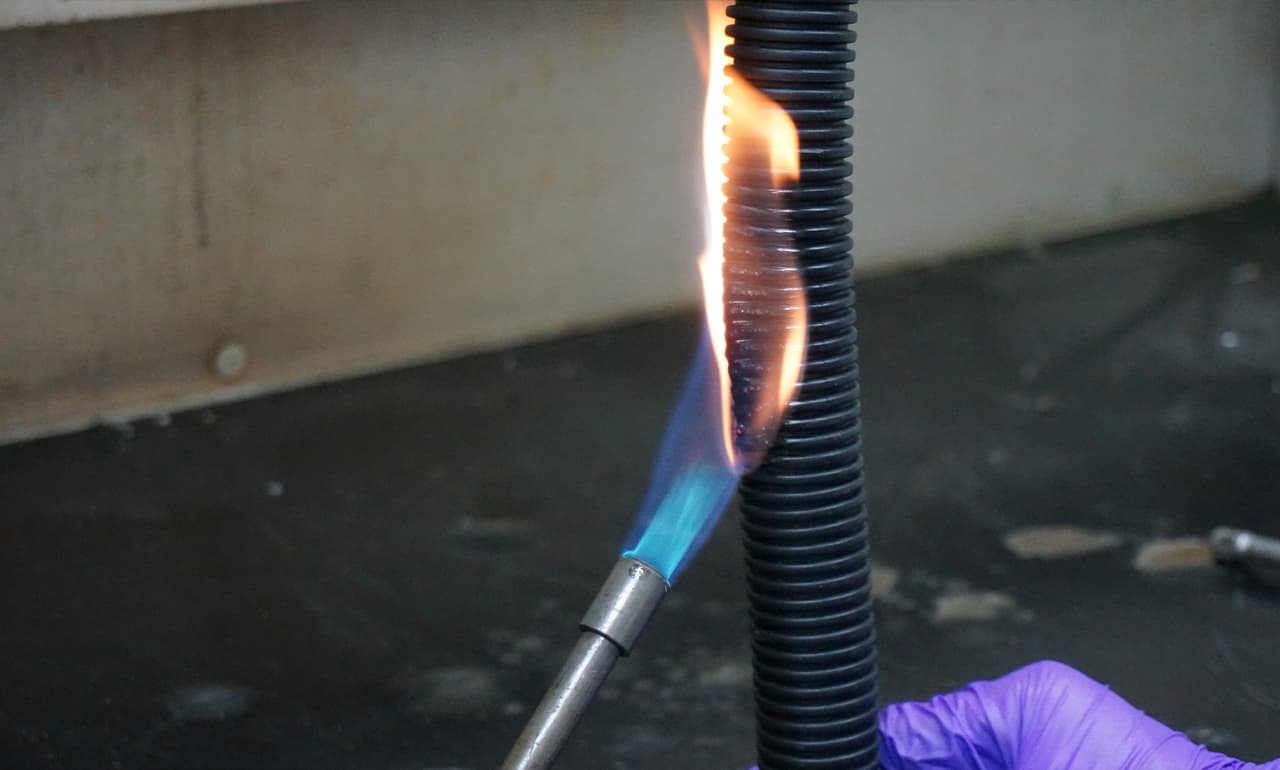

2. PF Fire Prevention Pipe

Developed by Sun Rise and Formosa Plastics, PF pipe has the same appearance, dimensions and mechanical strength as CD pipe. The difference is that the raw materials in PF pipes have fire-retardant ingredients.

Spec: OD 2.54cm and 5.08cm

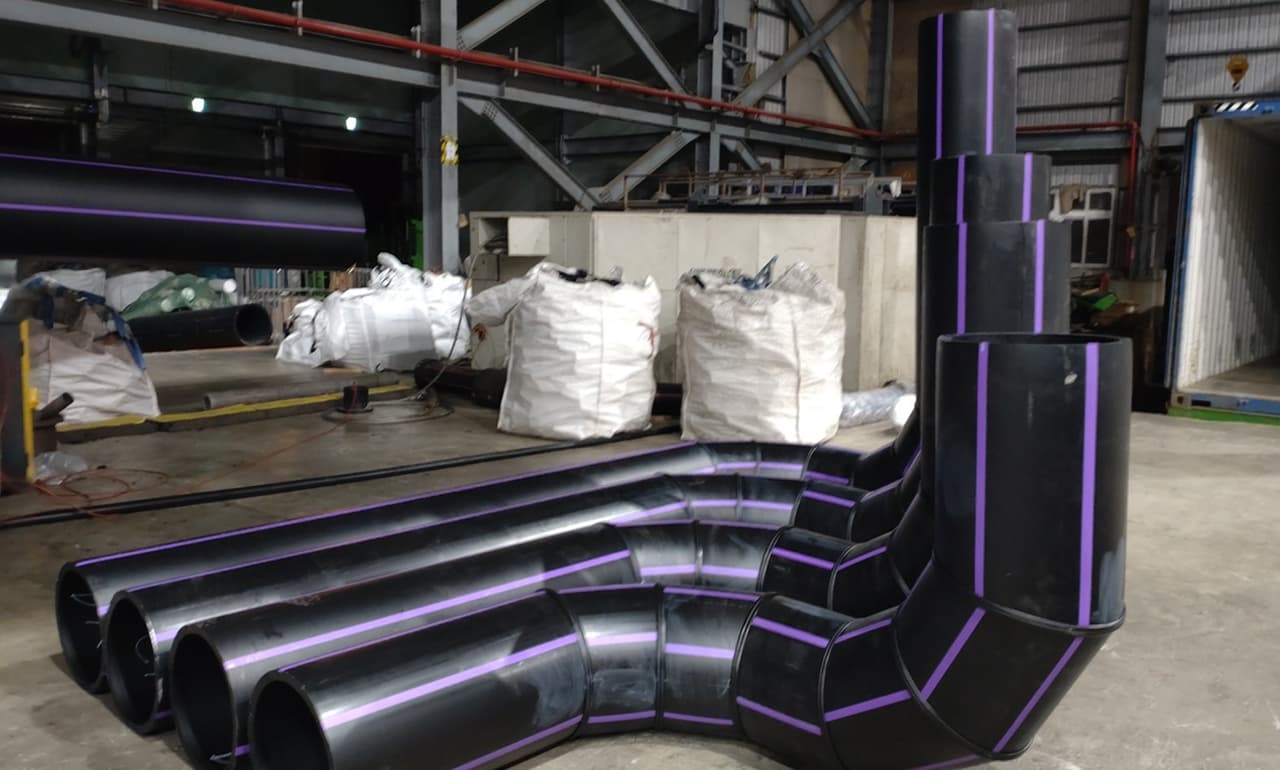

3. Special-shaped Pipe

“Special-shaped pipes" refer to those whose shapes and structures are different from standard round straight pipes. They are designed to meet specific application requirements.It has a wide range of uses, but it highly relies on the skills of technicians. Sun Rise has more than 20 years of construction experience, and our technology is widely recognized by large engineering companies around the globe. The following are some common types of special-shaped pipes and their applications:

- Elbow:

Application: for use in the corner. - Tee:

Feature: usually in T or Y shape.

Application: to separate one pipeline to two or combine two pipelines together. - Reducer:

Feature: to connect pipes of different diameters, and come in two forms - concentric and eccentric.

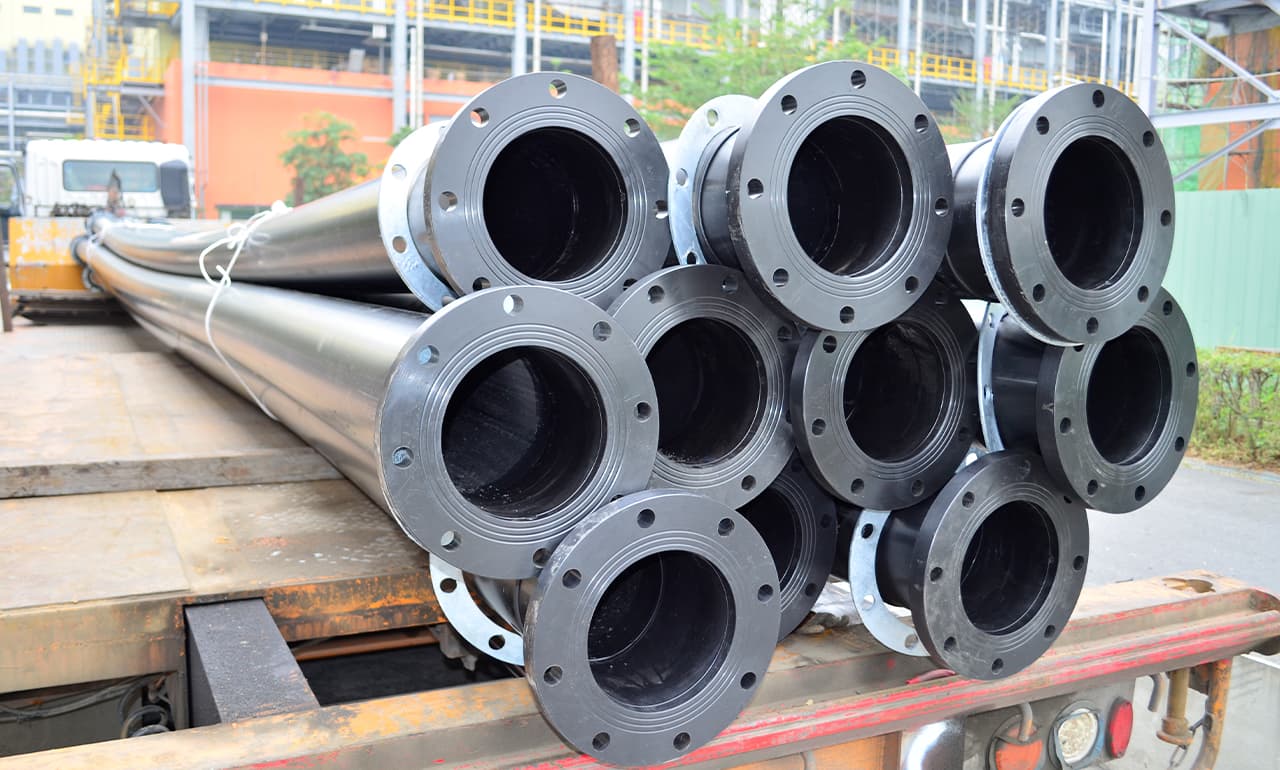

Application: used in the place where pipes of different diameters need to be connected. - Flange:

Feature: can be connected to other flange fittings or equipment.

Application: often used at pipe connections that need to be disassembled and repaired, such as pumps, valves and other equipment interfaces. - Other Pipe:

Features: including various special-shaped pipe fittings, such as four-way pipes.

Application: used for various purposes according to specific engineering requirements.

4. Pipe-in-pipe

"Pipe-in-pipe" is a special structure in which one or more pipes are placed inside an HDPE pipe. This design provides additional protection and insulation. It is often used in communications and electricity engineering in Taiwan. Also used in oil, gas and chemical liquid transportation and maritime engineering. Pipe-in-pipe has the following characteristics:

- Double-layer protection: the structure increases the overall strength and durability, and can effectively prevent damage to the internal pipes.

- Thermal insulation: the structure can effectively reduce heat transfer between pipes.

- Anti-leak design: If the inner pipe leaks, the outer pipe can be used to prevent the leakage from spreading into the environment. It is especially suitable for transporting hazardous substances.

- Easy maintenance: in some cases, this structure can make maintenance and replacement of inner tubes simpler without the need to damage the outer structure.

Specification: OD 34mm and 50mm

- Straight pipe: mostly delivered in this way

- Coil: pipe OD under 76.2 mm

- Naked packing: for black pipe

- PE bag: single PE bag available

- Crates: mostly for air shipments.

- Pallet: mostly for air shipments or LCL.

- Container: for oversea shipments. 40’/40’HQ is recommended.

- Trailer: for domestic shipments

Coil

PE bag

Crates

Container

Trailer